Ingersoll Rand Rotary Screw Compressor Manual

- Ingersoll Rand Rotary Air Compressor Manual

- Ingersoll Rand Rotary Screw Compressor

- Ingersoll Rand Rotary Screw Compressor Troubleshooting

Ingersoll Rand Rotary Screw Air Compressors The 5-15HP UP Series rotary screw compressors provide “best in class” performance in rotary screw technology. Each compressor package comes standard with 230/460-3-60 ODP electric motor, air-cooled after cooler to reduce discharge air temperatures, full voltage motor starter mounted and wired (wired for 230-3-60 voltage standard), dual control, low sound/ full sheet metal enclosure, package pre-filter, 8000-hour rated Ultracoolant, spin-on oil filter and separator element, A.S.M.E. Coded horizontal receiver tank (tank mounted units only) with manual drain, and NEMA-1 electrical protection. Looking to save space and installation costs? Consider the Small UP 5-15 HP “Total Air System” (TAS) packages as an innovative solution for your customer’s needs. TAS packages come standard with “Energy Star” cycling refrigerated air dryer with stainless steel heat exchanger, integrated compressor and dryer controls for optimum operation, panel mounted dew point indicator, dual filters (both pre and after) mounted and piped, single point condensate drain system with electric drain (115-volt), and high efficiency moisture separator. Model # Description CFM Price UP6-20-150 20hp, 120 Gallon Tank Mounted, 150 PSI, Voltage 208/240/460 77 UP6-20-125 20hp, 120 Gallon Tank Mounted, 125 PSI, Voltage 208/240/460 83 UP6-25-150 25hp, 120 Gallon Tank Mounted, 150 PSI, Voltage 208/240/460 94 UP6-25-125 25hp, 120 Gallon Tank Mounted, 125 PSI, Voltage 208/240/460 102 UP6-30-130 30hp, 120 Gallon Tank Mounted, 150 PSI, Voltage 208/240/460 115 UP6-30-125 30hp, 120 Gallon Tank Mounted, 125 PSI, Voltage 208/240/460 125 Controller Intellisys Controler Up-Grade SUK Start-Up Kit.

Package includes all UP Series standard features plus a low sound enclosure to lower the noise level to 69 dBA, ODP motor, after cooler, full voltage starter, load/no load with AS&S, NEMA 1 protection, and Ultra Plus coolant. Integral “non-cycling” refrigerated air dryer packaged into the compressor package. Dryer features “CFC-free” R404-A refrigerant and comes integrally packaged and wired to allow for a single point piping and electrical connection to the compressor package. Dryer features a built-in moisture separator and electric solenoid operated condensate drain–all pre-piped and wired. Ingersoll Rand Variable Speed Drive air compressors maximize the full potential of the VSD technology. Only Ingersoll Rand’s Nirvana VSD technology with the Hybrid Permanent Magnet® (HPM®) motor—the highest efficiency motor available—gives you all this: Unlimited starts/stops. Shuts off rather than run unloaded, conserving energy.

Ingersoll Rand Rotary Air Compressor Manual

Rated for continuous duty — 100% load, 24/7, 46°C (115°F) — to reduce downtime and lost production. Stable, constant pressure control Smooth soft-starting — starting amps always below full load.

Virtually no degradation in specific power at partial load. Variable speed blower allows the compressor to run at a constant discharge temperature. Automatic coolant temperature control to eliminate moisture build up. Xe-Series Controller The Xe-Series controller features an intuitive high resolution color display that provides a window into all vital compressor data. Remotely access and control your compressor from almost anywhere.

High intensity LED indicators clearly show compressor status from a distance. Sequence up to 4 Xe controlled compressors without any additional hardware. Customizable to operate in 30 different languages.

Real-time clock with scheduled start and stop ability. Web-enabled communication and control. Large navigation buttons and an intuitive menu layout for easy compressor control. Built-in performance analysis graphics and visual trending. Access automated inspection logs using a standard Web browser. Automatic email notification of warnings and trips.

Request a Quote: Ingersoll Rand Variable Speed Drive air compressors maximize the full potential of the VSD technology. Only Ingersoll Rand’s Nirvana VSD technology with the Hybrid Permanent Magnet® (HPM®) motor—the highest efficiency motor available—gives you all this: Unlimited starts/stops. Shuts off rather than run unloaded, conserving energy.

Rated for continuous duty — 100% load, 24/7, 46°C (115°F) — to reduce downtime and lost production. Stable, constant pressure control Smooth soft-starting — starting amps always below full load. Virtually no degradation in specific power at partial load. Variable speed blower allows the compressor to run at a constant discharge temperature. Automatic coolant temperature control to eliminate moisture build up. Xe-Series Controller The Xe-Series controller features an intuitive high resolution color display that provides a window into all vital compressor data.

Remotely access and control your compressor from almost anywhere. High intensity LED indicators clearly show compressor status from a distance. Sequence up to 4 Xe controlled compressors without any additional hardware.

Customizable to operate in 30 different languages. Real-time clock with scheduled start and stop ability. Web-enabled communication and control. Large navigation buttons and an intuitive menu layout for easy compressor control.

Built-in performance analysis graphics and visual trending. Access automated inspection logs using a standard Web browser. Automatic email notification of warnings and trips.

Request a Quote: Ingersoll Rand Variable Speed Drive air compressors maximize the full potential of the VSD technology. Only Ingersoll Rand’s Nirvana VSD technology with the Hybrid Permanent Magnet® (HPM®) motor—the highest efficiency motor available—gives you all this: Unlimited starts/stops. Shuts off rather than run unloaded, conserving energy. Rated for continuous duty — 100% load, 24/7, 46°C (115°F) — to reduce downtime and lost production. Stable, constant pressure control Smooth soft-starting — starting amps always below full load.

Virtually no degradation in specific power at partial load. Variable speed blower allows the compressor to run at a constant discharge temperature. Automatic coolant temperature control to eliminate moisture build up. Xe-Series Controller The Xe-Series controller features an intuitive high resolution color display that provides a window into all vital compressor data. Remotely access and control your compressor from almost anywhere. High intensity LED indicators clearly show compressor status from a distance. Sequence up to 4 Xe controlled compressors without any additional hardware.

Customizable to operate in 30 different languages. Real-time clock with scheduled start and stop ability.

Web-enabled communication and control. Large navigation buttons and an intuitive menu layout for easy compressor control. Built-in performance analysis graphics and visual trending. Access automated inspection logs using a standard Web browser. Automatic email notification of warnings and trips. Request a Quote: Ingersoll Rand Variable Speed Drive air compressors maximize the full potential of the VSD technology.

Only Ingersoll Rand’s Nirvana VSD technology with the Hybrid Permanent Magnet® (HPM®) motor—the highest efficiency motor available—gives you all this: Unlimited starts/stops. Honda zoomer 2016 specification. Shuts off rather than run unloaded, conserving energy.

Rated for continuous duty — 100% load, 24/7, 46°C (115°F) — to reduce downtime and lost production. Stable, constant pressure control Smooth soft-starting — starting amps always below full load. Virtually no degradation in specific power at partial load.

Ingersoll Rand Rotary Screw Compressor

Variable speed blower allows the compressor to run at a constant discharge temperature. Automatic coolant temperature control to eliminate moisture build up. Xe-Series Controller The Xe-Series controller features an intuitive high resolution color display that provides a window into all vital compressor data. Remotely access and control your compressor from almost anywhere. High intensity LED indicators clearly show compressor status from a distance. Sequence up to 4 Xe controlled compressors without any additional hardware.

Customizable to operate in 30 different languages. Real-time clock with scheduled start and stop ability. Web-enabled communication and control. Large navigation buttons and an intuitive menu layout for easy compressor control. Built-in performance analysis graphics and visual trending. Access automated inspection logs using a standard Web browser. Automatic email notification of warnings and trips.

Ultimate Reliability Fewer Connections ■ Smart integration eliminates leaks and pressure drops, maximising reliability. Ultimate Efficiency More Air for Your Money ■ Industry-leading performance delivers moreair for less horsepower, saving money on your energy bills. Smart, Energy-efficient Controls ■ Smart, energy-efficient controls eliminatewasteful unloaded running by unloading rapidly and by cycling the compressor on/off when not needed. Ultimate Flexibility Compact Footprint ■ Receiver mounting frees up valuable floorspace and reduces installation costs.

Ingersoll Rand Rotary Screw Compressor Troubleshooting

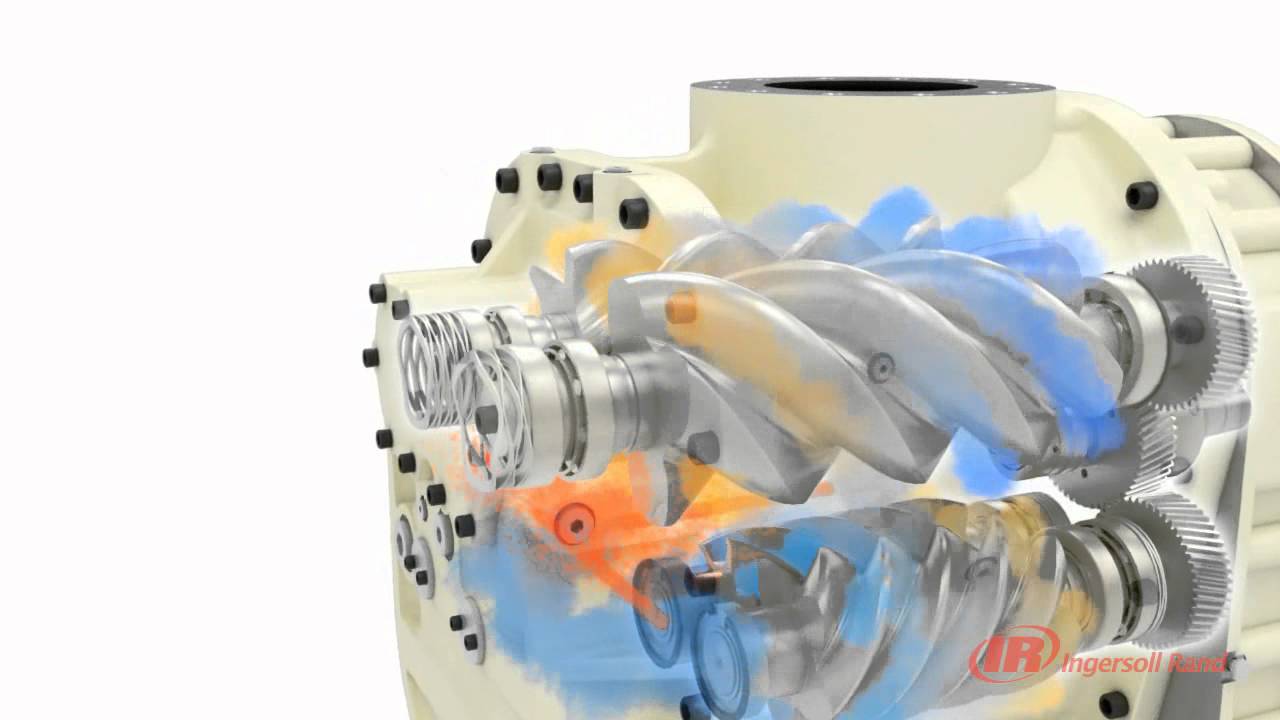

Installation Close to Point-of-Use. Innovation High-efficiency Integrated Compression Module To provide maximum performance, efficiency and ease of service, the airend, interconnecting piping and separation system have all been integrated into one simple design.

Integration of the high-efficiency compression module eliminates leaks and pressure losses to increase efficiency and performance.Service and maintenance are made extremelysimple through spin-on filtration and separator cartridges. Oversized, high-efficiency cooling air blower provides sound levels as low as 67 dB(A). Reliable and effective load/ no-load control with.

High-efficiency Filter Pack Energy-saving Refrigerated Air Dryer Clean Air to Drive Productivity Dry Air to Drive Productivity ■ Deep-bed general purpose filtration todeliver best performance, reduce pressure losses and extend operating life. ■ High-efficiency direct expansion refrigerated dryerautomatically starts with the compressor and operates continually. This operating cycle ensures immediate drying, reactive to the compressor loads. The dryer operates until the compressor unit is shut down. ■ Particulate removal to industry-leading 1 micron.

■ Longer element life, lower pressure. Smart Integration for 15-30 hp (11-22 kW) Advanced Packaging to Drive Reliability and Uptime ■ 'Dry' air receiver mounted in a compact package lowers the cost of installation (optional floor mount also available).

■ Integral air cooling with separate flow paths ensure cooling is achieved 100% of the time that the compressor is running. ֠ Easy access to all compressor and air treatment components, promoting serviceability. Probably the best-known name in compressor control systems, the optional Intellisys ■ Package pre-filter for longer component life and reducedmaintenance cost. Modular Cross Flow Heat Exchanger Leading Technology Driving Efficiency At the heart of the dryer lies the specially designed cross flow heat exchangermodule, incorporating air-to-air and air-to-refrigerant heat exchangers as well as a high-efficiency stainless steel de-mister condensate separator, all in one compact unit.Pre-cooling reduces the refrigeration load by as much as 60%. Air is further cooled through refrigerant heat exchange. Moisture is removed by the de-mister, close-coupled to the evaporator.The cross flow heat exchanger incurs minimum air pressure losses while ensuring efficient.

All INGERSOLL RAND catalogues and technical brochures.